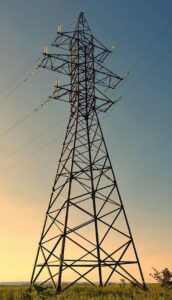

Transmission Line Towers

State of art design and manufacturing facility for Towers and Sub Station Structures up to 765KV

Design and development

- Electrical, Structural & Civil Designs of Transmission Line Towers form 11 kV to 765 kV, including preparing structural drawings, lay-out and Fabrication sketches.

- Route survey, profiling and tower spotting.

- Construction supervision.

- Special foundation design

- Preparation of Sag Template tables, preparation of Sag Template curves, drawing & preparation of Acrylic Sag Template for EHV Transmission lines.

- Environmental Impact Assessment (EIA)

Manufacturing

- State of art machineries capable of manufacturing of towers up to 765KV.

- Gas fired, automated temperature controlled, 8 mtr long galvanizing bath.

- In house testing facility.

- Strategic tie ups for material sourcing.

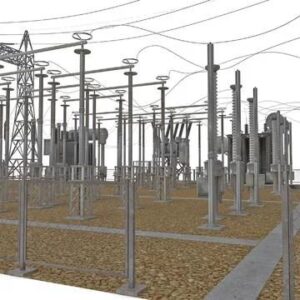

Sub Station

Design and development

- Concept to commissioning Engineering solutions to turnkeys projects of EHV sub stations.

- Preparation of specification for Substation equipment & construction thereof.

- Power flow and system studies and network analysis.

- Preparation of BOQ for sub stations up to 765 kV.

Manufacturing

- State of art manufacturing machines for typical structures of substations.

- Efficient sourcing eases prompt deliveries to urgent projects of Switchyard, gantry and equipment structures with even lesser quantity.

Solar Module mounting structures:

- Capable of supplying various type of structures for support of solar module mounting.

- Design and detailing adds value to the services as it offered with supply under one roof.

Lattice type wind mill towers:

8 mtr long bath and fabrication shop with sufficient material handling facility makes it possible to manufacture even present day hybrid tower design which consists of 80 mtr lattice parts

Manufacturing of Telecommunication towers

Design and manufacturing of ground based self supporting and roof mounting telecommunication tower is been done efficiently as team is well versed with resources and experience.

Heavy PEB and Chemical plant structures:

Dedicated machine lines of cutting, welding and shearing with 3 cranes of 5 MT capacity each and sufficient space for material storage and movement makes it efficient in handling and fabricating heavy sections.